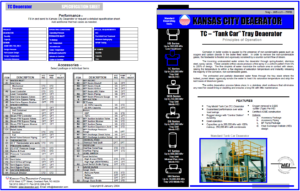

TC - Tank Car Tray Deaerator (Two Tank Welded)

Corrosion in boiler cycles is caused by the presence of non-condensable gases such as oxygen and carbon dioxide in the boiler feed water. In order to remove the non-condensable gases, the feedwater is heated and vigorously scrubbed by a counter current flow of steam.

The incoming undeaerated water enters the deaerator though spring-loaded, stainless steel spray valves. These variable orifice valves produce a fine spray in a uniform pattern from 5% to 200% of design. The fine droplets of water maximize the surface area in contact with steam, raising the temperature to within a few degrees of saturation temperature and instantly releasing the majority of the corrosive, non-condensable gases.

The preheated and partially deaerated water flows through the tray stack where the hottest, purest steam vigorously scrubs the water to heat it to saturation temperature and strips the last traces of dissolved gases.

The entire deaeration process takes place in a stainless steel enclosure that eliminates any need for vessel lining or cladding and ensures a long life with little maintenance.

Features

Selection Chart

10 Minutes Storage

|

Deaerator Model

(no pumps) |

Deaerator Model

(w/ pumps) |

Boiler

Capacity (HP) |

Rated

Capacity (#/HR) |

Storage to

Overflow (Gallons) |

Storage

Capacity (minutes) |

Water

Inlet ‘A’ (in) |

Steam

Inlet ‘B’ (in) |

Empty

Weight (lbs) |

Operate

Weight (lbs) |

Flooded

Weight (lbs) |

Price

|

|---|---|---|---|---|---|---|---|---|---|---|---|

|

319

|

11,000

|

231

|

10

|

2.5

|

3

|

2,800

|

5,000

|

7,000

|

Call

|

||

|

754

|

26,000

|

546

|

10

|

2.5

|

6

|

3,500

|

8,000

|

11,000

|

Call

|

||

|

870

|

30,000

|

629

|

10

|

2.5

|

6

|

4,500

|

10,000

|

16,000

|

Call

|

||

|

1,188

|

41,000

|

860

|

10

|

2.5

|

6

|

4,500

|

12,000

|

16,000

|

Call

|

||

|

1,304

|

45,000

|

944

|

10

|

2.5

|

6

|

4,700

|

12,000

|

18,000

|

Call

|

||

|

1,652

|

57,000

|

1,196

|

10

|

2.5

|

6

|

5,200

|

15,000

|

21,000

|

Call

|

||

|

2,203

|

76,000

|

1,595

|

10

|

3

|

8

|

6,100

|

20,000

|

28,000

|

Call

|

||

|

2,464

|

85,000

|

1,783

|

10

|

3

|

8

|

6,600

|

21,000

|

30,000

|

Call

|

||

|

2,899

|

100,000

|

2,098

|

10

|

3

|

8

|

7,100

|

24,000

|

34,000

|

Call

|

||

|

3,362

|

116,000

|

2,434

|

10

|

3

|

8

|

7,800

|

28,000

|

39,000

|

Call

|

||

|

3,536

|

122,000

|

2,560

|

10

|

4

|

10

|

8,600

|

30,000

|

48,000

|

Call

|

||

|

TC184-6016-150 (PKG)

|

4,348

|

150,000

|

3,147

|

10

|

4

|

10

|

9,200

|

35,000

|

50,000

|

Call

|

|

|

TC209-6016-157 (PKG)

|

4,551

|

157,000

|

3,294

|

10

|

6

|

10

|

9,400

|

36,000

|

52,000

|

Call

|

|

|

TC209-6516-170(PKG)

|

4,928

|

170,000

|

3,567

|

10

|

6

|

12

|

10,100

|

40,000

|

60,000

|

Call

|

|

|

TC246-6516-200(PKG)

|

5,797

|

200,000

|

4,196

|

10

|

6

|

12

|

10,700

|

45,000

|

62,000

|

Call

|

|

|

The above capacities are designed for 100% make up. For 50% make up and 50% condensate, increase capacities by 25%. i.e., A model TC246-6516 would be capable of 250,000 #/hr of 50% make up.

***Deaerator Models w/ pumps displayed in red are “Consult Factory” items*** |

|||||||||||

Accessories

|

ITEM

|

DESCRIPTION

|

ACC PKG

|

PUMP PKG

|

√

Select |

|---|---|---|---|---|

|

A

|

WATER INLET | |||

|

A1

|

Inlet Valve | |||

| Mechanical |

STD

|

STD

|

||

| Pneumatic |

OPT

|

OPT

|

||

|

A2

|

Level Controller |

STD

|

STD

|

|

| Level Transmitter |

OPT

|

OPT

|

||

|

A3

|

Inlet Valve Bypass Valves |

OPT

|

STD

|

|

|

A4

|

Inlet Valve Bypass Piping |

OPT

|

STD

|

|

|

A5

|

Inlet Valve Bypass Strainer |

OPT

|

STD

|

|

|

B

|

STEAM CONTROL | |||

|

B1

|

Steam PRV |

OPT

|

||

| Self Contained |

OPT

|

OPT

|

||

| Pneumatic |

OPT

|

OPT

|

||

|

B2

|

Steam PRV Controller |

OPT

|

OPT

|

|

|

B3

|

Steam PRV Bypass Valves |

OPT

|

OPT

|

|

|

B4

|

Steam PRV Bypass Piping |

OPT

|

OPT

|

|

|

B5

|

Steam PRV Bypass Strainer |

OPT

|

OPT

|

|

|

C

|

RELIEF VALVE | |||

|

C1

|

Relief Valve | |||

| Sentinel |

STD

|

STD

|

||

| Full |

OPT

|

OPT

|

||

|

C2

|

Relief Valve Exhaust Piping |

OPT

|

OPT

|

|

|

D

|

THERMOMETER | |||

|

D1

|

(2) 5″ Thermometer w/ss wells |

STD

|

STD

|

|

|

E

|

PRESSURE GAUGE | |||

|

E1

|

(1) 4 1/2″ Pressure Gauge |

STD

|

STD

|

|

|

E2

|

Siphon & Cock |

STD

|

STD

|

|

|

E3

|

Pressure Transmitter |

OPT

|

OPT

|

|

|

F

|

VENT | |||

|

F1

|

Vent Valve |

STD

|

STD

|

|

|

F2

|

Vent Orifice w/ Flange |

OPT

|

OPT

|

|

|

F3

|

Vent Bypass Valves |

OPT

|

OPT

|

|

|

F4

|

Vent Bypass Piping |

OPT

|

OPT

|

|

|

H

|

VACUUM BREAKER | |||

|

H1

|

Vacuum Breaker |

STD

|

STD

|

|

ITEM

|

DESCRIPTION

|

ACC PKG

|

PUMP PKG

|

√

Select |

|---|---|---|---|---|

|

M

|

BFP RECIRC | |||

|

M1

|

BFP Recirc Shutoff |

N/A

|

OPT

|

|

|

M2

|

BFP Recirc Check |

N/A

|

OPT

|

|

|

M3

|

BFP Recirc Orifice |

N/A

|

OPT

|

|

| BFP Recirc ARC Valve |

N/A

|

OPT

|

||

|

M4

|

BFP Recirc Piping |

N/A

|

OPT

|

|

|

M5

|

BFP Recirc Pressure Gauge |

N/A

|

OPT

|

|

|

N

|

BFP SUCTION | |||

|

N1

|

BF Pumps | |||

| (2) 100% Capacity |

N/A

|

STD

|

||

| (3) 50% Capacity |

N/A

|

OPT

|

||

| Motors | ||||

| ODP |

N/A

|

STD

|

||

| TEFC |

N/A

|

OPT

|

||

|

N2

|

BFP Suction Isolation Valve

|

N/A

|

STD

|

|

|

N3

|

BFP Suction Strainer

|

N/A

|

STD

|

|

|

N4

|

BFP Suction Piping

|

N/A

|

STD

|

|

|

N5

|

BFP Suction Expansion Joint

|

N/A

|

STD

|

|

|

N6

|

BFP Discharge Pressure Gauge

|

N/A

|

OPT

|

|

|

N7

|

BFP Discharge Check Valve

|

N/A

|

OPT

|

|

|

N8

|

BFP Discharge Isolation Valve

|

N/A

|

OPT

|

|

|

O

|

CHEMICAL FEED

|

|||

|

O

|

Chemical Feed Quill

|

OPT

|

OPT

|

|

|

Q

|

OVERFLOW

|

|||

|

Q1

|

Overflow Valve/Trap

|

STD

|

STD

|

|

|

Q3

|

Overflow Piping

|

OPT

|

STD

|

|

|

R

|

LEVEL SWITCHES

|

|||

|

R1

|

Level Switches

|

|||

| High and Low (TWO) |

STD

|

STD

|

||

| High High (ADDITIONAL) |

OPT

|

OPT

|

||

|

R2

|

Level Switch Bridle Piping

|

OPT

|

OPT

|

|

|

S

|

GAUGE GLASS

|

|||

|

S1

|

Gauge Glass

|

|||

| Red Line Pyrex |

STD

|

STD

|

||

| Reflex |

OPT

|

OPT

|

||

| Magnetic |

OPT

|

OPT

|

||

|

S2

|

Gauge Glass Bridle

|

OPT

|

STD

|