Since our founding in 1989, Kansas City Deaerator has become a major force in the global market of deaerators and deaerator components in both the utility and industrial sectors.

Kansas City Deaerator Company

Our expertise comes from years of training at Chicago Heater Company in the mid 1970’s where Chicago Heater was one of the leading Utility and Commercial Deaerator suppliers in the world. Our founder Mike Koontz and others have designed over 50 Utility Tray and Spray Deaerators over 5,000,000 lbs/hr up to some of the largest in the world, over 10,000,00 lbs/ hr. Our customer list is extensive and includes most large Engineering firms in the World. In addition, we have a long list of satisfied customers in the Utility and Power Deaerators, Power Generation, Petroleum, Petro-Chemical, Pulp and Paper industries.

Deaerator Types

Kansas City Deaerator Company designs a complete line of Deaerator Types and Sizes, from Spray to Tray deaerators, smallest to the largest in the world.

TRAY DEAERATORS

Tray deaerators are the ultimate choice by all reputable Consulting Engineers all over the World. Tray Deaerators ( Only Counterflow types, not Parallel Downflow Types) are the only Deaerators approved by the Heat Exchange Institute HEI as they keep all gasses contained in Stainless Steel to protect the Carbon Steel vessel from Corrosion. Tray Counterflow deaerators are the Gold Standard and choice of most owners where longevity and trouble free operation is needed for over a 25 year life. Spray Deaerators and Counterflow Deaerators simply do not meet the requirements of the HEI.

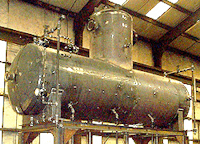

Horizontal Counterflow Tray Heater on a horizontal Storage. For larger sizes 800,000#/ hr to 16,000,000 #/hr with larger storage volumes 10 minutes and up.

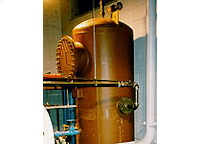

Vertical Counterflow Tray Heater Supported on a horizontal storage. For Medium Sized units 250,000 #/hr to 800,000 #/hr with Larger Storage Volumes 10 to 15 minutes and up.

Vertical Counterflow Tray Heater welded Directly to a horizontal Storage. For small units 0 #/hr up to 250,000 #/ hr with larger 10 to 15 minutes storage

Vertical Counterflow Tray Deaerator with integral Storage. For small to Medium sized units 0 #/hr to 800,000 #/hr

SPRAY DEAERATORS

Spray Deaerators typically have a lower life. The design will result in a 20-30 % reduction in Cost. But does not meet the HEI.

Horizontal Spray Deaerators range in Size Fro 0 #/ hr to 250,000 #/ hr with large storage requirements. However can range to over 6,000,000 #/ hr.

Vertical Spray Dearators up to 1,000,000 #/ hr are used when there is little plan area, excessive headroom and little Storage needed ( 5 minutes).

About Us

Michael Koontz

Mike Koontz graduated from the University of Kansas with a degree in Engineering and a Masters in Business Administration. The founder of KCD and with over 30 years, the longest member of any member in the Heat Exchange Institute. Experience and maintenance upgrades include Chicago Heater Company, Graver Deaerator, Ecodyne Deaerator, Stickle Steam, PMI Deaerator, Great Lakes Water, Envirex Deaerator, American Water Softening HOH Deaerator LA Water, Crane Cochrane, Belco, Industrial Steam and Cleaver Brooks Among others.

Global Capabilities:

Kansas City Deaerator Company has the capability and relationships to fabricate in almost any country. From SE Asia to India, Saudi Arabia, Europe and Korea. In addition to supplying the complete deaerator, KCD will design your deaerator and supply the key drawings and components such as trays, spray valves, and inspections.

Customers:

Some of our customers are: Black & Veatch, Burns & McDonnell, Bechtel, GE, Consolidated Edison, Dow, Union Carbide, Hitachi, Fluor, Chiyoda, Calpine, Siemens, Stork Deaerator, Kawasaki, Cerrey, Wood Group, ESI, Raytheon among hundreds of others.

Trade Associations:

HEI : Heat Exchange Institute:

Kansas City Deaerator was one of three founding members who reinstated the Heat Exchange Institute for deaerators in 1990. Original Members were Kansas City Deaerator Company, Permutit and Stickle Steam. Since that time Mike Koontz has served as the longest member of the Heat Exchange Institute serving in many capacities, including Vice President and President of the deaerator section and Vice President and President of the General Membership. Since the reinstatement of the deaerator section Kansas City Deaerator was instrumental in writing a majority of the current HEI specification for deaerators over the last 30 years.

ABMA:

Kansas City Deaerator is a past member of the American Boiler Manufactures Association.

ASME:

Dave Stewart is on the ASME pressure vessel committee and has served for over 10 Years. Dave’s experience helps KCD stay in touch with updated ASME Vessel requirements as well as suggesting improvements to the ASME Specification.

EPRI:

Kansas City Deaerator has written papers for EPRI on deaerator maintenance repairs and design to reduce or eliminate FAC Flow accelerated Corrosion in Deaerators. for deaerator testing.

ASTM PTC 12.3 Deaerators

Kansas City Deaerator was a past member of the ASTM PTC 12.3 Performance Test Code for Deaerators and keeps updated to date. Few changes have been made over the years.