Deaerator Case Studies

CHICAGO HEATER REPLACEMENT VENT

Problem: The deaerator had water out the vent.

CHLORIDE ATTACK TRAY ENCLOSURE

Problem: The tray enclosure was ineffective due to chloride attacks on the deaerator.

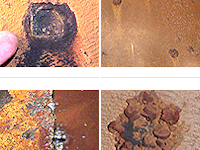

CORROSION

Problem: Corrosion pits were observed in the deaerator storage section.

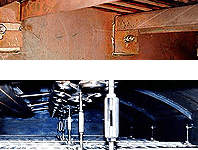

DEAERATOR EROSION

Problem: A deaerator was thinning out due to erosion underneath the tray stack.

DOG LEG VENT PIPE FAILURE

Problem: Many manufacturers provide a dog leg type vent with a miter joint which typically fails due to inadequate welding where the vent pipe supports the valve plate.

FLOW ACCELERATED CORROSION (FAC)

Problem: Vessel had severely high corrosion due to FAC.

HEATER STEAM EROSION

Problem: Various locations of the deaerator and heating section can be eroded by steam due to inadequate downcomer sizing, inadequate baffling and inadequate water distribution.

HIGH OXYGEN LEVELS

Problem: The customer complained about poor dissolved oxygen readings.

SCRUBBER MODIFICATION

Problem: The deaerator scrubber was inadequately sized and destructed due to high velocities.

SPRAY DEAERATOR CORROSION

Problem: The deaerator is open to oxygen degradation due to non containment of the oxygen in the vessel.

SPRAY DEAERATOR WATER BYPASS

Problem: Water is bypassed in this spray deaerator due to high flow rates and/or inadequate sizing of tray pans

STRESS CRACK IN VESSEL SHELL

Problem: Cracking in deaerators is most often attributed to corrosion fatigue, where a crack results from a cyclic stress in a corrosive environment.

TRAY BOX SUPPORT PITTING

Problem: Pitting was noticed on the supports of tray box.

TRAY ENCLOSURE SUPPORT WEAR

Problem: The tray enclosure supports were ruined due to relatively high steam velocities and water erosion.

TRAY HOLD-DOWNS

Problem: Tray holdowns on older units rely on sheer force to the tray box to compress the trays and hold the trays down.

TRAY UPSETS

Problem: Tray upsets are common in the deaerator industry if proper tray hold-downs and baffling are not provided.

WATERBOX SPRAY PATTERNS

Problem: Spray valves were improperly located over the trays allowing for water carry over to the vent

WELD OVERLAY ON DEAERATOR

Problem: Excessive pitting and/or erosion due to high velocity of steam and the deaerator will not perform properly.